Blurred Vision Car Audio & Electronics llc

Blurred Vision Audio BV-PROSM1244(Shallow Mount)

Blurred Vision Audio BV-PROSM1244(Shallow Mount)

Couldn't load pickup availability

🔊 Blurred Vision Audio BV-PROSM1244 Shallow-Mount Subwoofer

Looking to upgrade your Small vehicle/truck’s sound system but short on space?

Meet the Blurred Vision Audio BV-PROSM1244, the ultimate shallow-mount subwoofer built to deliver massive bass performance in tight spaces.

With an ultra-slim mounting depth under 4 inches, this powerhouse fits effortlessly behind seats or in compact enclosures—without sacrificing output. Don’t let its size fool you—this sub hits hard.

💪 Built for Power and Precision

3" 4-layer aluminum voice coil delivers powerful, punchy, and crystal-clear bass.

High-density foam surround and precision-tuned spider suspension ensure consistent, distortion-free performance.

Large, vented magnet structure provides superior cooling, keeping your sub running strong even under heavy use.

⚙️ Performance Highlights

Ultra-slim profile for tight-space installations

Powerful, efficient motor for hard-hitting low frequencies

Multiple venting and cooling chambers prevent overheating

Durable design built to handle continuous high-power operation

🚗 Style Meets Substance

From its sleek design to its thunderous sound, the BV-PROSM1244 is as clean-looking as it is powerful. Whether you’re cruising or competing, this shallow-mount monster will turn heads—and shake cabins.

Don’t let space limit your sound.

Upgrade your system with the Blurred Vision Audio BV-PROSM1244 today and experience deep, rich, and solid bass that transforms your ride.

Perfect — with those specs, here’s a clean, professional, and consistent product specification sheet for the Blurred Vision Audio BV-PROSM1244, formatted to match the tone and style of your other models:

🔊 Blurred Vision Audio BV-PROSM1244 – Shallow Mount Subwoofer

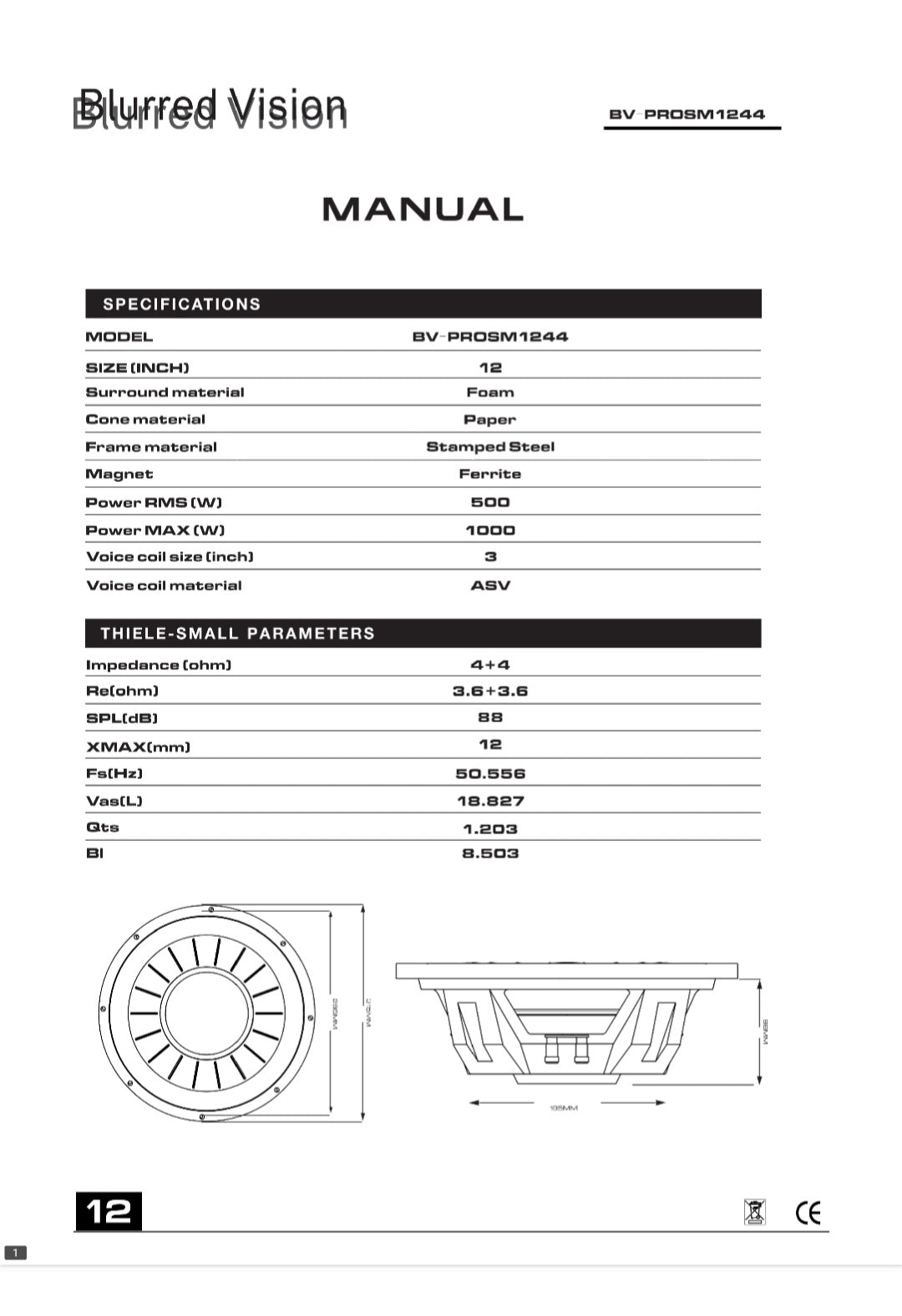

📋 Specifications

Feature Specification

RMS Power 500 Watts

Max Power 1,000 Watts

Impedance Dual 4 Ω (D4)

Mounting Depth Under 4"

Sensitivity 86 dB

Magnet Size 80 oz

Voice Coil 3" Copper, 4-Layer Aluminum Former

Basket Type Rigid Stamped Steel

Weight 12 lbs

⚙️ Performance Highlights

Ultra-slim design fits easily in tight spaces without sacrificing bass response.

3-inch copper voice coil delivers clean, punchy low-end and excellent heat dissipation.

Rigid stamped steel basket provides structural strength and durability.

Large vented 80 oz magnet ensures consistent cooling and powerful performance.

High-efficiency design for maximum output even with limited amplifier power.

🚗 Compact Size, Monster Sound

The BV-PROSM1244 proves that big bass doesn’t require big space. With under 4" of mounting depth, it’s the perfect solution for trucks, SUVs, and vehicles where space is tight—but sound quality is non-negotiable.

Experience tight, punchy, and accurate bass in a sleek, space-saving design built for both daily driving and show-stopping performance.

Quick driver reminders (from sheet)

12″ driver, RMS 500 W

Vas = 18.827 L (≈ 18.4 L used below)

Fs = 50.56 Hz

Qts = 1.203

Xmax = 12 mm

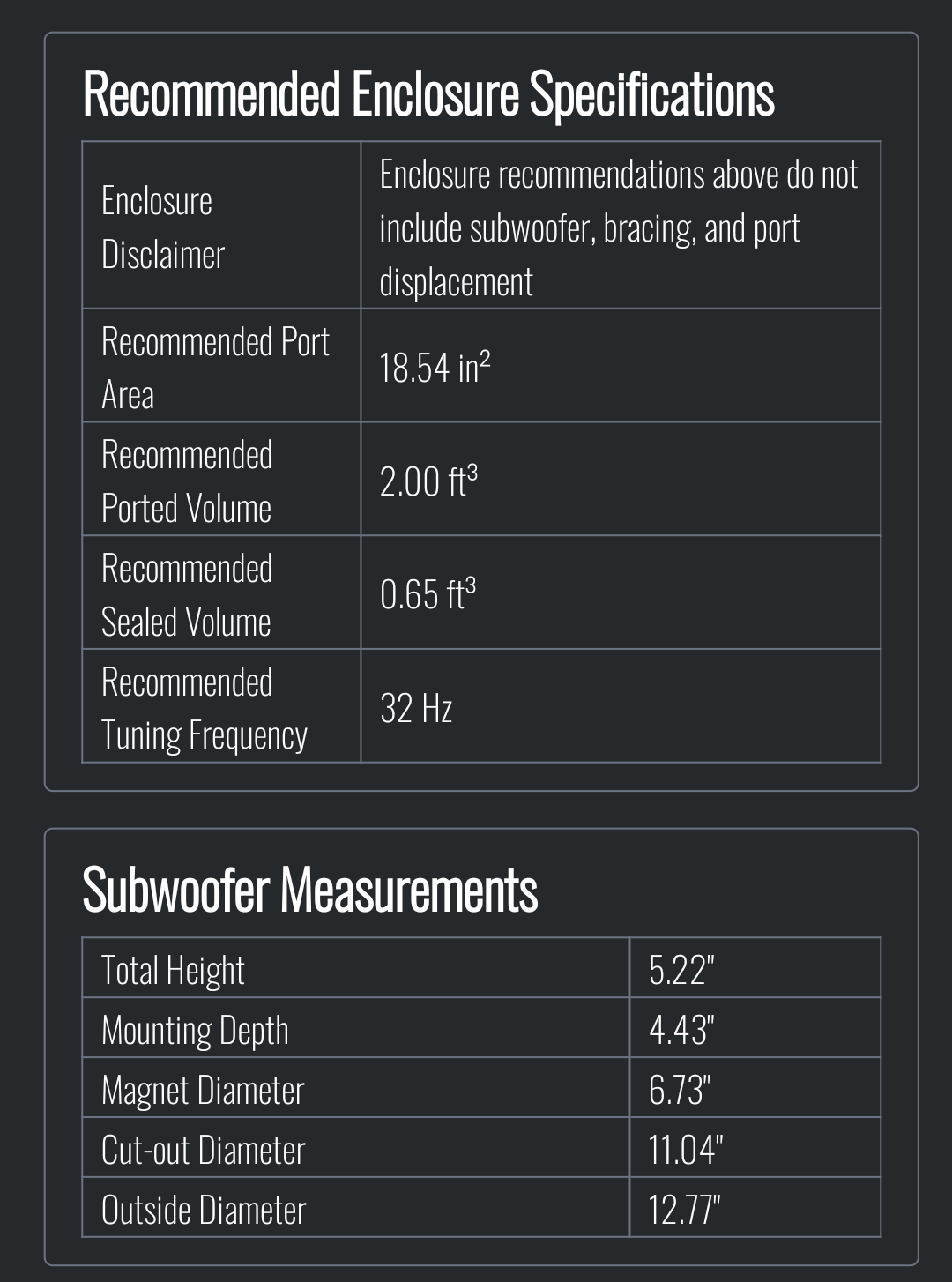

(*Option A)— Compact Sealed enclosure (tight, punchy)

Goal: ~0.65 ft³ (net internal) ≈ 18.4 L (compact, good transient response for daily music)

Internal net volume: 0.65 ft³ = 18.4 L

Internal dimensions (example, chosen to comfortably fit a 12″ driver):

Internal Width = 14.00″

Internal Height = 14.00″

Internal Depth = 5.73″

(14 × 14 × 5.73 = ~1123 in³ = 0.65 ft³)

These keep the driver centered on a square baffle and keep depth slightly greater than driver mounting depth (5.13″) to allow for basket/terminal clearance.

Material & thickness: (0.75) MDF.

Panel cut sizes (single-panel method; dimensions are external panel sizes):

Thickness (t) = 0.75″. External W/H = 14 + 2t = 15.42″. External Depth = 5.73 + 2t = 7.15″.

Front / Back: 15.42″ × 15.42″ (2 pcs)

Left / Right sides: 7.15″ × 15.42″ (2 pcs)

Top / Bottom: 14.00″ × 7.15″ (2 pcs) — note: top/bottom are cut to internal width × external depth so they fit between the sides/front/back.

Driver cutout: Typical 12″ subwoofer mounting cutout ≈ 11.0–11.5″ (depending on your driver’s mounting flange). Use the driver template (measure your driver). Provide 8–12 mounting holes depending on driver pattern.

Terminal cup: place on rear panel centered about 1″ above bottom inside for easy wiring.

Internal bracing & damping:

Use a vertical brace across the middle if you feel the panels will flex.

Use polyfill/pillow stuffing lightly (cover ~30–50% of internal volume) to smooth response.

Sealing & gasket:

Use a good gasket (foam or rubber) around the driver flange.

Glue seams with wood glue and seal with silicone on inside for airtightness.

Expected response: Sealed with this small volume and driver Fs~50 Hz + high Qts, expect tight punch and strong mid-bass but limited low-end extension below ~40–50 Hz compared to a ported box. Good for music that needs fast transient response.

(*Option B) — Ported (Slot) enclosure tuned to 36 Hz (deeper low bass)

Goal: 0.65 ft³ net internal, tuned to 36 Hz using a slot port (fits into small enclosures using an L-shaped port run inside).

Net internal volume: 0.65 ft³ (18.4 L) — same as above. (If you want extra low-end or easier port geometry, increase to 0.75–0.9 ft³.)

Tuning frequency (Fb): 36 Hz

Port area (given / used): 10 in² (common slot area used previously)

Calculated effective port length:

Using the Helmholtz approximation for V = 18.4 L and A = 10 in² → effective length ≈ 31.8″ (≈ 0.81 m).

That is an effective length measured from inside face to effective end corrections; with a slot port this is typically implemented as an L-shaped slot inside the box, or a long rectangular port that folds inside the cabinet.

Practically: create an internal slot that has physical length ~30–33″ of airflow path (folded L-shape inside the enclosure) to achieve ~36 Hz. Because the physical port length is often folded, it fits in compact enclosures.

Slot port options (examples):

*Option 1 (single rectangular slot): 2.0″ × 5.0″ = 10 in² (physical slot). Required effective length ~ 32″ (fold this length into two runs inside the box — e.g., two 16″ runs stacked).

*Option 2 (narrower, taller slot): 1.25″ × 8.0″ = 10 in² → same length required. Choose geometry that fits your cabinet layout.

If you want a circular port instead, area-equivalent diameter ≈ 3.6″ (circle area = 10 in² → d ≈ √(4A/π) ≈ 3.57″). A circular port of 3.6″ diameter would require the same ~32″ effective length.

Recommended port layout (folded slot inside):

Build the box internal as Option A (14″ × 14″ × 5.73″ internal) and allocate an internal partition to create an L-shaped slot that gives 30–33″ of internal length. Example: cut a slot 2″ × 5″ in the front baffle area, then route an internal partition that turns the slot and runs along the bottom or side inside the box for the remainder of the length. Seal all joints so the slot is an open rectangular duct.

Panel cut list: same base panels as sealed option, plus 1 or 2 internal partitions sized to create the folded slot duct. Design those partitions to be slightly smaller to allow assembly (e.g., two pieces 13.5″ × 5.4″ cut to suit internal layout).

Driver cutout & placement: mounting baffle front-center same as sealed. Place port exit at front or side — slot front-facing or bottom-facing works well for compact builds.

Damping & stuffing: ported boxes typically use less stuffing. Add small amount of polyfill near walls (not in the port path). Polyfill can help simulate slightly larger volume if desired.

Expected response: Extends lower than sealed (down to low 30s depending on tuning), with more output around tuning frequency (36 Hz) but less tight transient than sealed. Because Qts is high (1.203) this driver will be somewhat “boomy” in ported alignments if not tuned carefully — keep power and enclosure stiffness high and use bracing to avoid panel rattles.

Build notes & tips (both designs)

Measure driver flange & basket before cutting the driver hole — templates vary. The driver requires ~5.13″ depth; ensure the internal depth allows for magnet and terminal clearance.

Glue + Screws: Use wood glue on all seams and clamp; screw from outside. Seal inside with silicone to be airtight.

Bracing: For a small 12″ box, at least one internal brace is recommended to reduce panel flex.

Finish: Paint, vinyl wrap, carpet, or veneer after sealing & testing.

Test: After build, test for air leaks using a smoke or paper test and check for rattle with moderate SPL before final finish.

If driver displacement matters (magnet and voice coil), subtract driver displacement volume from net internal — I used gross approximations; if you want precise net volume including driver displacement and port internal volume, I can recalc.

Which one should you build?

If you want tight, accurate punch for daily music: build the sealed 0.65 ft³ box.

If you want more low-end extension and louder bass at 30–40 Hz for music/club style: build the ported box tuned to 36 Hz with the long folded slot (remember the long ~32″ effective port run).

Share